Infrascan

EV Charging Points, Electrical Installation, Electrical Maintenace, Thermographic Surveys

OZEV APPROVED

NICEIC APPROVED

INFRASCAN

Infrascan were formed in 1999 and offer a unique electrical Service.

Our Core business is EV Charging points, Electrical Installation, Electrical Maintenace and Thermographic Surveys.

Infrascan are a leading supplier and installer of electric car charging points. Installations start at a competitive price and are covered by a 3-year manufacturer's warranty, and a 10-year Warranty on the installation. Choose from our range of chargers. We now install Rolec, Project EV, Pod Pont and Zaptec to name a few.

We are OLEV approved.

We are NICEIC registered, so our work is guaranteed for 10 Years.

We carry out electrical works on Industrial, commercial and Domestic and have been NICEIC Registered for 12 years.

Our Core business is EV Charging points, Electrical Installation, Electrical Maintenace and Thermographic Surveys.

Infrascan are a leading supplier and installer of electric car charging points. Installations start at a competitive price and are covered by a 3-year manufacturer's warranty, and a 10-year Warranty on the installation. Choose from our range of chargers. We now install Rolec, Project EV, Pod Pont and Zaptec to name a few.

We are OLEV approved.

We are NICEIC registered, so our work is guaranteed for 10 Years.

We carry out electrical works on Industrial, commercial and Domestic and have been NICEIC Registered for 12 years.

car electrical chage point

Infrascan Services are becoming leaders in the installation of Charge points for Electrical Vehicles.

A charging point for your home makes it faster, safer and more convenient to charge your vehicle. No more extension leads, worrying about plug connections outside or wondering whether you are overloading your home’s electrical supply.

Infrascan Services will advise you on the type and positioning of your charge point and install a dedicated electrical circuit. This will be installed to the current IEE Regulations and all work will have a 10 Year labour warranty and 3-year parts warranty.

Do not have your charger incorrectly installed. The DNO (Distribution Network Operator) in the majority of installation must be informed before the charger unit is installed. Only then once the DNO approved the charger can be installed.

We check out the existing Electrical installation to ensure it is adequate, and above all it is safe to install a charger unit.

Why do you need to use an OLEV installer.

- We are Government approved which means we can help with all applicable grants.

- Infrascan Services carry a large stock of home chargers so we can fit fast and with no fuss.

- Government body The Office for Zero Emission Vehicles (OZEV) provides grant funding for installations at residences with private parking and EVHS eligible vehicles.

- The grant is obtained only through a registered and approved OZEV installer such as Infrascan Services.

- For more details on OZEV and why you require an approved OZEV installer visit the OZEV website

EV Charging at home

The safest and most effective way to charge your electric vehicle at home, is with an EV home charger. With a range of EV Charging Devices available on the market, you’ll have a plethora of options to choose from. Whether you want a device that charges your electric vehicle using renewable energy sources, or one that provides insights and features through a companion app, there’s a charger out there to suit every home.

A 7kW (kilowatt) EV charge point will provide up to 30A to your vehicle – adding between 20 and 30 miles of range to your vehicle for every hour it is plugged in.

Using a domestic socket to charge your vehicle will supply about 10A (amps) to your vehicle – which will add between 3 and 10 miles of range per hour of charging time. However, it’s important to take into account that 3-pin charging cables aren’t as safe as a fully installed charge point. The electrical demand from charging your EV can become too much and can potentially cause a fire. For this reason, it is not a recommended form of EV charging, and most professionals strongly advise against using this method

A 7kW (kilowatt) EV charge point will provide up to 30A to your vehicle – adding between 20 and 30 miles of range to your vehicle for every hour it is plugged in.

Using a domestic socket to charge your vehicle will supply about 10A (amps) to your vehicle – which will add between 3 and 10 miles of range per hour of charging time. However, it’s important to take into account that 3-pin charging cables aren’t as safe as a fully installed charge point. The electrical demand from charging your EV can become too much and can potentially cause a fire. For this reason, it is not a recommended form of EV charging, and most professionals strongly advise against using this method

EV CHARGING POINT

Infrascan working closely with our partners Hypervolt, Rolec, Project EV, Podpoint, Zaptec, toname a few, and we can offer the following:

SAFETY IN THE

HOME CERTIFIED

3 YEAR PARTS WARRANTY

AND 10 YEAR LABOUR WARRANTY

INCLUDED FREE

INCLUDED FREE

MANUFACTURED

IN THE UK

IN THE UK

MOBILE APP CONTROLLED

SMART CHARGING

SMART CHARGING

IP RATED &

UV STABILISED

UV STABILISED

Our partner suppliers of EV Equipment have been established for many years and have the experience in the EV industry, Our Partners have designed, manufactured and Infrascan Services is one of the companies who have installed electric vehicle charging points across some of the most renowned locations amongst numerous industries. From EV charging solutions for the home, commercial locations, workplaces and fleets, Infrascan services and our Patners provides an exceptional service led by a team of dedicated experts. Whilst offering the UK’s largest range of AC Fast and DC Rapid charging points, we have the reputation for delivering cost-effective, scalable solutions to suit all budgets and requirements. The extensive range of Rolec EV charging points has proven to be a success amongst many electrical contractors and Infrascan are one of the leading installers.

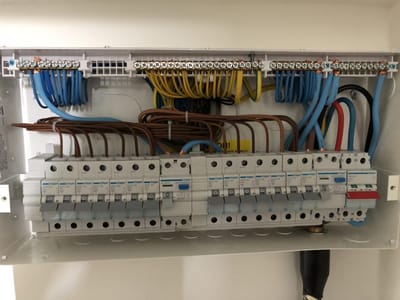

Electrical installation

Infrascan has been carrying out work on all kinds of electrical installation since 1999 and we consider ourselves to be one of the best companies to assist and carry out your electrical requirements.

All our electricians are fully trained and respectable.

We will carry out any works. from changing a light fitting to a rewire of a property.

All our works are guaranteed for 10 years.

Where required installation certificates are issued and Building control is notified.

Infrascan electricians are fully certified and experienced in a variety of electrical services for homes and businesses. Providing planned and reactive solutions day and night, our experts in domestic and commercial installation are the ones to call for all of your electrical needs.

From wiring repairs to lighting installation and rewires, Infrascan have got it covered.

We have been operating in Coventry for almost 25 years and during this time have built up a reputation for providing exceptional electrical services. This is because our local electricians are dedicated to providing the highest level of service on all occasions.

All our electricians are fully trained and respectable.

We will carry out any works. from changing a light fitting to a rewire of a property.

All our works are guaranteed for 10 years.

Where required installation certificates are issued and Building control is notified.

Infrascan electricians are fully certified and experienced in a variety of electrical services for homes and businesses. Providing planned and reactive solutions day and night, our experts in domestic and commercial installation are the ones to call for all of your electrical needs.

From wiring repairs to lighting installation and rewires, Infrascan have got it covered.

We have been operating in Coventry for almost 25 years and during this time have built up a reputation for providing exceptional electrical services. This is because our local electricians are dedicated to providing the highest level of service on all occasions.

electrical maintenace

An electrical installation comprises all the fixed electrical equipment that is supplied through the electricity meter. It includes the cables that are usually hidden in the walls and ceilings, accessories (such as sockets, switches and light fittings), and the consumer unit (fusebox) that contains all the fuses, circuit-breakers and, preferably residual current devices (RCDs)*.

There are many factors that contribute to a good electrical installation such as:

- Ensuring there are enough sockets for electrical appliances, to minimise the use of multiway socket adapters and trailing leads

- Covers are in place to prevent fingers coming into contact with live parts (broken or damaged switches should be replaced without delay)

- A Residual Current Device (RCD) protection is installed to provide additional protection against electric shock

- Satisfactory earthing arrangements are in place to ensure that a fuse or circuit breaker can quickly clear an electrical fault before it causes an electric shock or fire

- Satisfactory protective bonding arrangements are in place where required (so any electric shock risk is minimised until a fault is cleared)

- Sufficient circuits are provided to avoid danger and minimise inconvenience in the event of a fault

- Cables are correctly selected and installed in relation to the fuse or circuit breaker protecting the circuit

*An RCD (residual current device) is a life-saving device which is designed to prevent you from getting a fatal electric shock if you touch something live, such as a bare wire. It provides a level of protection that ordinary fuses or circuit breakers cannot provide.

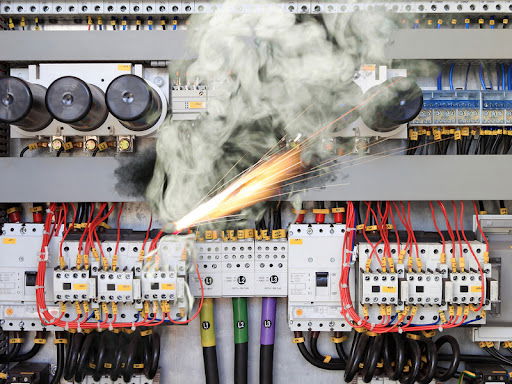

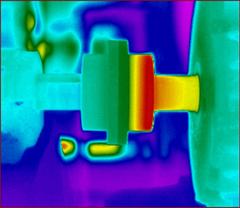

THERMOGRAPHIC SURVEYS

We carry out surveys on Electrical, mechannical and refractory plant.

infrared thermography is a test that can be utilised to identify unbalanced loads, poor connections, deteriorated insulation or any other issues in energized electrical panels or components without dismantling the components. These problems may lead to excess power use, increased maintenance costs, or catastrophic equipment failure resulting in unscheduled service interruptions, equipment damage, or other problems.

The NFPA or National Fire Protection Association assesses that 10% of the fires happening are associated with electrical system failures, like failure of terminals, electrical insulation and related components. Electricity at Work Regulations Act 1989, Health & Safety at Work Act 1974 and BS 7671 (IEE Wiring Regulations 17th Edition as amended) suggest that electrical infrastructure be regularly maintained and tested to ensure compliance with safety guidelines.

Performing an infrared testing will highlight problems with electrical infrastructure under load during the testing process as these areas will manifest as anomalous temperatures shown in the live image on the thermal imaging camera. Moreover, failures can result in employees to be bared to live electrical circuits, making them prone to severe injury or death from electrocution. By detecting high-resistance connections and repairing them, the likelihood of a breakdown of the electrical wires and related components will be reduced.

Other benefits of finding and fixing these faults are the cost effectiveness that comes from energy conservation and reduction in shutdown and repair charge. High resistance in circuits causes an increase in current flow. When current flow is increased, the resulting power consumption will increase. Additionally, large current draw can lead to severe electrical circuit components, like circuit breakers, fuses and transformers, to collapse prematurely. These failures result in higher maintenance and repair costs, and resultant business interruptions.

Benefits of Doing Thermography Testing of Electrical Panel

- Determines if the components and system have been properly installed and are not damaged

- Reduces downtime

- Reduces risk of equipment failure

- Increases safety

- Improves insurability

- Reduces liability exposure of the designers and installers

- Improves system performance

- Determines whether components and systems operate properly and meet the design intent

- Determines if components and systems are in compliance with the project specifications and design

- Reduces construction schedule delays

- Saves money

Testimonials

Customers

Contact

- HARVEY CLOSE coventry